INDUSTRIAL ENAMEL FRIT FOR GGH

GET FREE SAMPLES!General Usage:

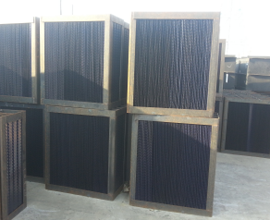

It is a anti-acid industrial enamel frit, very strong acid resistance, corrosion resistance, specially for Heat Exchangers / GGH(Gas-Gas heater).

Product Description:

1, Applied to heat exchanger(GGH) in thermal power plant, air pre-heater, chemical vessel, reactor, stirring paddle, etc…

2, With low firing temperature, high re-sintering resistance.

3, Good operating performance, strong enamel surface.

4, High level chemical corrosion resistance.

| Mill Formula | |

| RTU3550 | 100 |

| Clay | 5-6 |

| Quartz | 0-5 |

| Borax | 0.5-0.8 |

| Sodium nitrite | 0.2 |

| Water | 50-55 |

| Firing Temperature(℃) | 820-860 |

| Enamel Features: | |

| Adherence | at least number 1 |

| Acid-resistance level | AA |

| Coefficient of thermal expansion | 277.1 |

| Health Information |

| This industrial enamel frit does not contain Pb, Hg, Cd, Cr+6 |

For enamel coating problems, you must be troubled!

1, Bad Surface Appearance: Black dot on white cover coat

2, Weak Adhesion Low impact resistance, easily broken

3, Fish-scale problem

For bad coating, Nolifrit can help you!

No black dot

Strong adhesion

No fish-scale

Nolifrit Advantages

26 Years of Technical Accumulation

- Focus on the research and development of enamel frit and enamel pigment for 26 years.

- Foreign experts joined, always stay on the cutting edge of technology in enamel industry.

30,000 MT Enamel Frit Annual Capacity

- Standarded EIA and ISO quality assurance.

- With large capacity and on-time delivery, huge cost advantage.

500 Customers over the world

- Nolifrit Can Offer Enamel Coating Solution within 48 hours.

- Nolifrit Will Offer Door-To-Door Technical Service If Customer Need.

Exported to 30 Countries and Areas

- High quality enamel frit and Cadmium red pigment can satisfy most of Europe and America customers.

- Mostly export to mid-to-high level customers in Taiwan, Southeast Asia, South America.

Customer Evaluations

Professional BBQ Manufacturer in North America Mr. Jacky .Carl

We bought from Ferro(USA) before, and we started to try Nolifrit 10 years ago, then I never going to change supplier again. Nolifrit enamel frit quality stable , and their technical support without any delay. The most important is that they help us to save more than 20% enamel raw material cost, which makes us more competitive in the market.

The Most Famous Cast Iron Enamel Cookware Manufacturer in Europe Ms. Rose . Diane

FREE SAMPLES, please add WhatsApp +86-13574208778 , Email: jack@nolifrit.com OR fill out the following form. We will respond to you as soon as possible.