Hardness of enamel coating

As we all know, the enamel frit is a kind of high temperature and corrosion-resistant composite material. In addition to the field of daily necessities, it is also widely used in the industrial field. But many times my friends want to know the hardness of the enamel frit after covering it on the metal material. Is the enamel frit abrasion resistant or not? This article Nolifrit will focus on sharing the hardness of enamel frit and the factors that affect the hardness of enamel frit.

Hardness is the ability of an object to resist being drawn or pressed into its surface by other objects. Hardness is represented by Mohs hardness (scratch method), Indentation hardness (indentation method), Rebound hardness (wear method), etc. Depending on the measurement method used, the hardness of the enamel varies, and the hardness of the enamel is generally measured by the Mohs hardness.

Generally, the Mohs hardness of the enamel layer is 5 to 7.

The hardness of enamel has a great relationship with the composition of its formula. Na2O、K2O、PbO, etc. will reduce the hardness of enamel; CaO、MgO、BaO、ZnO、Li2O, etc. can increase the hardness of enamel. Replacement of SiO2 with Al2O3 in aluminosilicate system enamel can increase hardness. In boroaluminate, when n (Na2O) / n (B2O3)> 3, if Al2O3 is used to replace part of SiO2, the hardness is increased; When n (Na2O) / n (B2O3) <1, if SiO2 is also replaced by Al2O3, the hardness will decrease.

Grinding and introducing quartz, clay, zirconia, sodium metaantimonate, etc. will increase the hardness of enamel. Adding an excessive amount of electrolyte, especially when it causes the enamel surface to boil, causes its hardness to decrease greatly.

Generally, enamel with high hardness has better acid resistance than enamel with lower hardness.

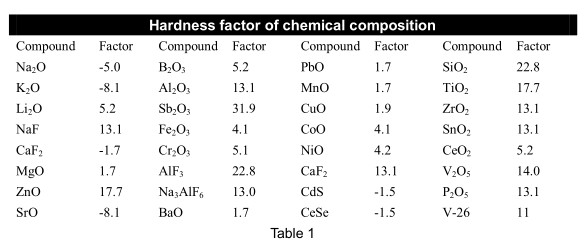

Within a certain range, the hardness of enamel can be calculated according to the following formula:

Hm=(w1H1+ w2H2+…+ wnHn)/250

In the formula:

Hm——Mohs hardness of enamel;

wn——mass fraction of each chemical component of enamel;

Hn——hardness factor of each

chemical component of enamel (Table 1).

As far as practical application is concerned, chute beneficiation equipment such as coal chute is one of the fields where the wear resistance of enamel frit is fully exerted. It makes full use of the enamel frit that can be tightly combined with the steel plate material. At the same time, the enamel frit is harder than ordinary minerals, so it can greatly reduce the wear on the conveying equipment during the transportation of minerals. In addition, the pumps for coal water slurry, beneficiation wastewater, etc. And the coating of enamel frit in pipes can greatly extend the service life of the equipment, and because the enamel frit has a smooth surface similar to glass, it can reduce fluid resistance and energy consumption.

In short, enamel materials not only wear-resistant, but also have high temperature and corrosion resistance, and will definitely play a more prominent role in high-tech fields such as information, biology, energy, environmental protection and space. There are many types of enamel materials, and they are widely used. They have a very broad market prospect and are of great strategic significance.