Five Types of Enamel Pigment

With the development of the enamel industry, enamel products have been given more and more colors, and the fields of application have become more and more extensive. Common and simple colors such as red, yellow and black can no longer meet the needs of enamel, and sometimes other pigments such as emerald green, cream yellow, peach red, lilac purple, lake blue, and pearlescent pigments are needed.

Enamel has high chemical stability and high temperature stability for pigments, and is not easy to fade, discolor, etc. There are usually the following 5 common types of enamel pigments that meet the requirements:

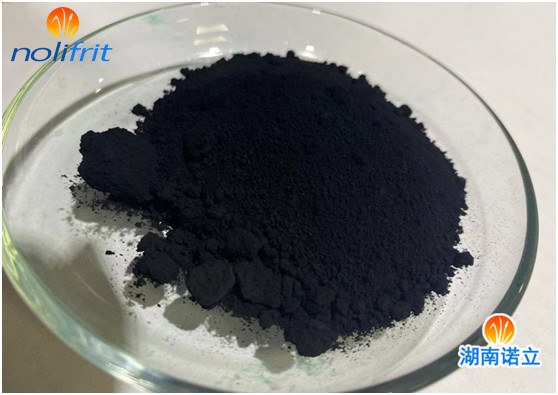

1. Spinel pigment

The general chemical formula of spinel pigment is XO`Y2O3, X is a divalent cation, such as cobalt, nickel, copper, zinc, magnesium, iron, manganese, calcium, etc., and Y is a trivalent cation such as cadmium, manganese, iron, aluminum Wait. Our common copper chrome black pigment is this type, which has good high temperature resistance and is superior to iron oxide black and carbon black.

2. Cadmium pigments

The most typical cadmium pigment is cadmium yellow (CdS) and cadmium red (CdSeS). Cadmium pigments are generally only used in transparent frit or translucent frit. If part of the sulfide of the cadmium pigment is oxidized into part of the sulfate, a misty sulfate film will be formed on the surface of the enamel. The surface of the enamel can be rinsed with water, drained and then fired again. Cadmium-based pigments cannot be used for enamel cookware, tableware, etc. that come into contact with food.

3. Encapsulated Pigments

Because cadmium-based pigments may be decomposed at temperatures above 880°C, if they are wrapped with transparent zirconium silicate crystals, cadmium-based pigments that are still stable at high temperatures of 1400°C can be made. This pigment can be used not only in enamel frit, but also in the coloring of ceramics.

4. Zirconium and tin pigments

This pigment is formed by the combination of colored oxides and leuco-based silicic acid and tin oxide, and is often used in ceramics or light-colored enamels. There will be various reducing impurities in the enamel frit, which will cause the pigment to partially fade, and the surface of the enamel after firing has white spot defects, which can be solved by grinding and adding 0.5% soda ash to the enamel slurry.

Common pigments of zirconium series: zirconium iron red, fruit green, vanadium blue, etc.;

Tin-based pigments: peach red, rose red, etc.

5. Pearlescent Pigment

The enamel porcelain surface made of pearlescent pigments can produce a sparkling effect like pearls or fish scales. Pearlescent pigments are sensitive to firing temperature, and lower firing temperature is beneficial to them. They can only be used in special transparent enamel frit. It is necessary to add pearlescent pigments and stir evenly after the enamel frit is worn out.