What should enamel manufacturers do when glaze slurry performance is unstable?

The properties of enamel glaze slurry determine whether it can be evenly applied to metal surfaces. In actual production at enamel manufacturers, glaze slurry may exhibit poor flowability and yield properties. When applied to the substrate, it fails to achieve uniform coverage, leading to uneven coating and resulting in defects such as pores and pinholes that severely impact product appearance and quality. This is closely related to the content of grinding additives during porcelain glaze grinding, the composition of the clay, and the type of porcelain glaze used.

Beyond issues of poor flowability and yieldability, another challenging problem arises—particle settling. Particles suspended in the glaze slurry, much like silt in water, gradually sink under gravity over time. This causes the slurry to stratify, rendering the entire glaze system highly unstable. Once the slurry's stability is compromised, subsequent production stages become akin to building skyscrapers on shifting sands. With such unstable foundations, consistent product quality becomes virtually impossible to guarantee.

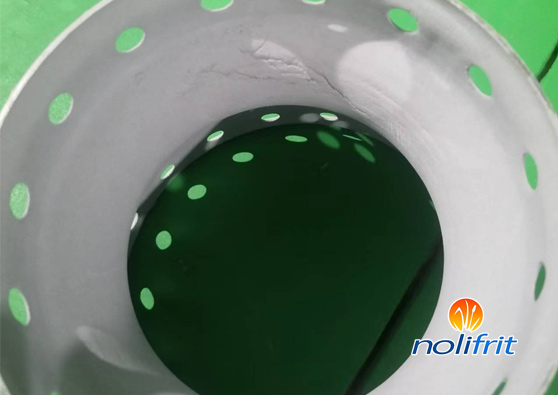

As a manufacturer of enamel glaze, Noli addressed this critical challenge by developing an enamel RTU powder. This innovative solution effectively enhances glaze slurry viscosity and suspension capacity even at low moisture levels. It acts like buoyancy for the particles, enabling them to remain stably suspended in the glaze slurry for extended periods. This ensures consistent glaze slurry performance, providing a solid foundation for subsequent production processes.

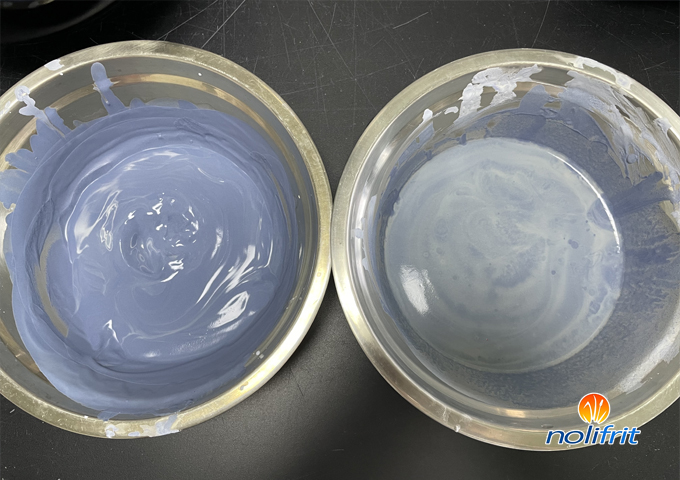

Additionally, Noli provides technical support to address the unstable glaze slurry performance issues faced by enamel manufacturers. For instance, when encountering glaze slurry stratification problems, Noli's technical engineers effectively resolve these challenges by adding nitrite. Nitrite exhibits excellent dispersibility and stability. Adding an appropriate amount of nitrite to the enamel RTU powder effectively prevents glaze slurry stratification and enhances the performance of the enamel ready-to-use powder.