Types And Selection of Steel Enamel Ground Coat

There are many types of steel enamel ground coat. According to the temperature, it can be divided into low temperature (Soft): 780℃~820℃, medium temperature (Middle): 820℃~850℃, and high temperature (Hard): 850℃~880℃. According to the adhesive, there are cobalt ground coat, nickel ground coat, cobalt nickel ground coat, antimony ground coat and antimony molybdenum ground coat. Enamel manufacturers can find professional enamel frit suppliers to choose suitable enamel frits according to their own production requirements.

1. Cobalt ground coat (CoO)

Cobalt ground coat is an enamel ground coat with cobalt oxide as the adhesion agent. Generally, the introduction amount of cobalt oxide is about 0.5%. If it is a daily use enamel, the introduction amount is generally 0.5%~0.8%. For cast iron sanitary ware or acid-resistant industry, the amount will be about 0.2%~2.6%.

2. Nickel ground coat (NiO)

Nickel ground coat is an enamel ground coat that uses nickel oxide as the adhesion agent. The adhesion ability of nickel oxide is slightly worse than that of cobalt oxide, so the amount of introduction is higher, usually 1% to 2%.

3. Cobalt-nickel ground coat (NiO, CoO)

Cobalt-nickel ground coat is a ground coat that simultaneously introduces cobalt oxide and nickel oxide as adhesion agents. Cobalt-nickel ground coat is one of the most popular varieties of enamel manufacturers. This kind of ground coat has a strong adhesion ability, so you only need to add a small amount to the ground coat. The adhesive can exert a very good effect. It is suitable for industrial parts, steel plate utensils, kitchen cooking utensils, stoves, etc. The resulting enamel products have fine porcelain surfaces, high gloss (glossy frit), and excellent acid resistance. However, the cost is higher and it is suitable for medium and high-end products.

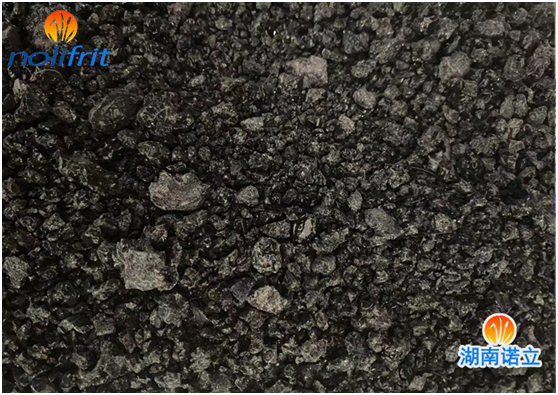

4. Antimony ground coat (Sb2O3)

Antimony ground coat is a ground coat with antimony oxide as the adhesion agent. Generally, a part of antimony oxide is first melted into the ground coat, and then a part of antimony oxide is ground when the ground coat is ground into a slurry. Its adhesion ability is not as good as that of the nickel and cobalt-nickel ground coat. And because it contains antimony, it is not suitable for some applications where antimony is restricted, but its price is low, and it is suitable for medium and low-end products.

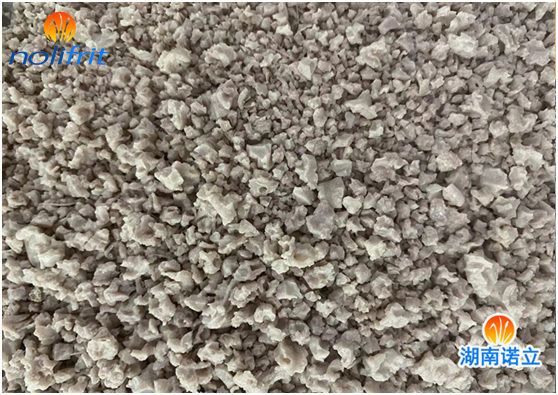

5. Antimony molybdenum ground coat (Sb2O3, MoO)

Antimony and molybdenum ground coat also uses antimony oxide and molybdenum oxide as adhesion agents. Its adhesion ability is not worse than that of cobalt ground coat and nickel ground coat, but it is cheaper and more cost-effective. This kind of enamel frit can meet the requirements of various pigments, can ensure that the colored enamel frit has bright color, stable tone and good chemical stability, and can make the colored enamel frit have strong hiding power and tinting power.

Nolifrit is a professional manufacturer of enamel frits. When customers need to customize and buy enamel frits, Nolifrit can provide customers with very complete product services, technical support and solutions, and help customers create special products. Welcome to leave message to us!