Test Method For Fish Scale Sensitivity of Steel

Once the fish scale problem occurs in enamel products, the damage to the quality and qualification rate of the product is fatal. When choosing a steel plate for enamel, the enamel manufacturer must choose an enamel steel plate with good anti fish scale performance, so how to judge the steel plate What are the advantages and disadvantages of anti fish-scale performance? Nolfriti provides you with 4 practical methods.

Method 1: Hydrogen Permeation Experiment

The hydrogen permeation test is an electrochemical method for determining the diffusion rate of atomic hydrogen in metals. A special hydrogen permeation rate measuring device is required, which can obtain the hydrogen permeation curve of the tested sample. If the penetration time of hydrogen in the steel plate is longer (more than 100s) or the hydrogen diffusion coefficient is smaller, the anti fish-scale performance of the steel plate is better. However, the hydrogen permeation test is not suitable for all enamel steel plates. If the hydrogen permeation test cannot be used for the steel plate, the enamel fish scale test can be carried out by using enamel sensitive to fish scale.

Method 2: Accelerated Fish Scale Experiment

The steel plate is placed in a constant temperature environment of 250 °C for 9 hours or a constant temperature environment of 200 °C for 24 hours, and then quenched (by water quenching), and finally the sensitivity of the steel plate to anti fish-scale is evaluated according to the fish scale.

Method 3: Visual inspection and intuitive experiment

Directly observe and record the situation of enamel in different time periods after firing, such as cooling, 1h, 12h, 24h, 2 days, 3 days, 7 days and 15 days after being baked, which is also the most commonly used method by enamel manufacturers at present.

Method 4: Fish scale sensitive enamel experiment

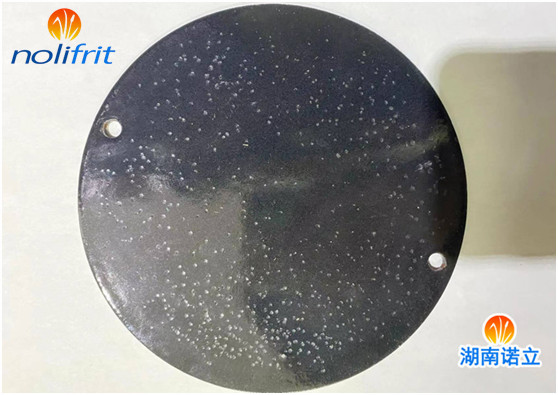

The sensitivity of the steel plate to anti fish-scale is evaluated according to the number of fish scale by coating the steel plate with enamel frit which is very sensitive to fish scale after firing.

In addition to doing the fish scale test of enamel steel plate to test the anti fish-scale performance of steel plate, in order to reduce the occurrence of fish scale, enamel manufacturers can also use professional anti fish-scale enamel frit to reduce cost loss and improve product quality.