How to Test Acid Resistance Level for Enamels

The applications of acid resistant enamel coating is more and more widely, especially in mid and high level market. It’s not only applied in industrial area, where chemical resistance and long lasting durability against the elements is key, but also in our daily life, like enamel cookware and enamel water heater tank.

How to test acid resistance level for porcelain enamel coating?

Nolifrit follows a very serious and effective testing method for this.

Testing Reagent:

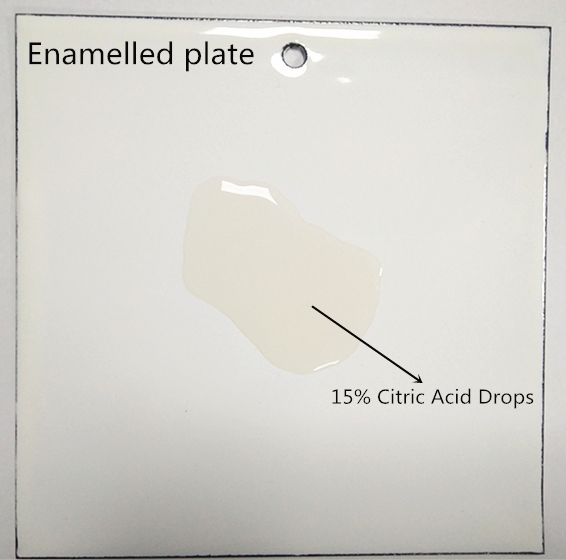

15% citric acid is used in this test. It’s reacted on the enamel coating surface and the result can be seen by virtual observation.

Testing Step:

1, Place some drops of citric acid liquid on enamel coating surface.

2, Cover the dropped enamel coating surface for 15 minutes.

3, Wash the test plate, to do the follow tests:

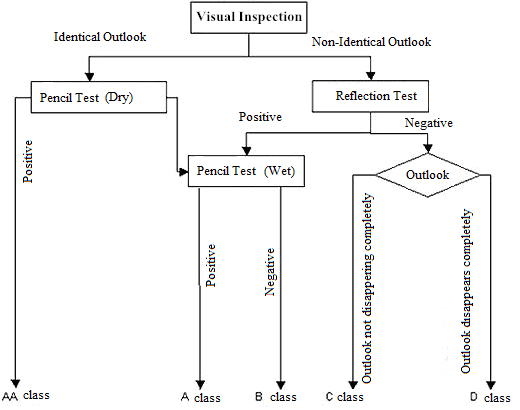

A, Visual Inspection

To inspect the two enamel coating areas directly by eyes. If there is obvious difference between the acid applied area and the regular enamel coating surface, the result is negative.

B, Pencil Test( dry)

Two parallel lines are drawn between the acid applied enamel coating area and the regular enamel coating surface by a pencil. Two lines are swabbed by a dry towel. If it is harder to swab the acid applied enamel coating area than the regular enamel coating area, the result is negative.

C, Reflection Test:

A light source is reflected on the acid applied enamel coating area and the regular enamel coating area. If there is a dim reflection on the acid applied enamel coating surface, the result is negative.

D, Pencil Test( wet)

The test in item B is applied by a wet towel. If it is harder to swab the acid applied enamel coating area than the regular enamel coating area, the result is negative.

Hunan Noli Enamel Co., Ltd is the leader manufacturer of porcelain enamel frit for vitreous enamel coating in China. Focused on enamel coating solutions for almost 30 years.

We have many kinds of enamel frit and enamel powder (ready to use powder and electrostatic powder) with high acid resistance level AA. They are widely used in enamel cookware, enamel storage tank, GGH(gas gas heater) and heater exchangers.