Features Required For Steel Enamel Ground Coat

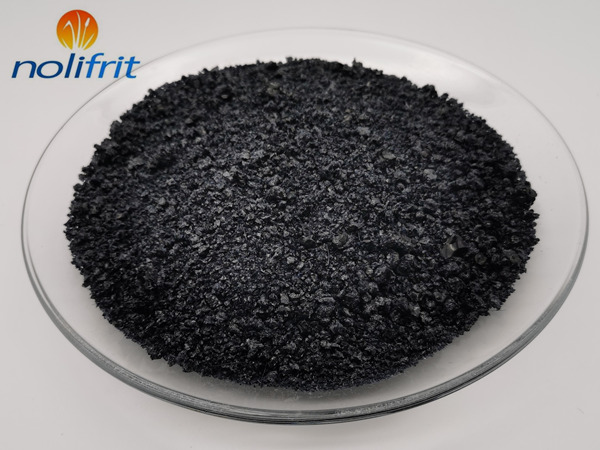

Enamel ground coat is an enamel frit that is directly applied to the metal body. The choice of enamel ground coat plays a decisive role in the internal and external quality of enamel products. When choosing steel plate enamel ground coat, what aspects should everyone pay attention to? What are the characteristics that steel plate enamel ground coat should have?

Characteristics of steel plate enamel

ground coat:

1. Good adhesion:

the steel plate enamel ground coat needs to be well combined with the metal substrate.

2. The firing temperature of the commonly used ground coat should be slightly higher than the firing temperature of the enamel cover coat by 20-30 ℃. If the firing temperature of the ground coat is lower than the firing temperature of the cover coat, it will be cause discoloration or boiling of cover coat during the firing process of the cover coat.

3. The firing temperature range of the ground coat is usually around 60 degrees Celsius.

4. The ground coat melt should have a good ability to infiltrate the metal, the surface tension should be low, the viscosity should be low, the fluidity should be good, and can dissolve a large amount of iron oxide on the surface of the metal substrate, so that the ground coat and the metal can be firmly bonded.

5. The ground coat should have an expansion coefficient compatible with the metal. When the enamel product is fired, the ground coat and the metal body are firmly combined. If the expansion coefficients of the two are not compatible, the porcelain enamel layer will crack or fall off. .

6. The ground coat of steel plate enamel must also have good elasticity and compressive strength.

The above is the summary made by Hunan Noli Enamel Co., Ltd on some of the characteristics of steel plate enamel ground coat. We hope these little knowledge can be helpful to everyone. Nolifrit has 26 years of experience in the enamel industry, mainly engaged in enamel frit, enamel RTU powder, electrostatic powder and enamel pigments. For more enamel knowledge, please follow us. For consultation and cooperation or free sample testing, please contact online customer service or directly call +8613574208778.