New Application of Enamel: Enamel Mouthpiece Components for E-Cigarettes

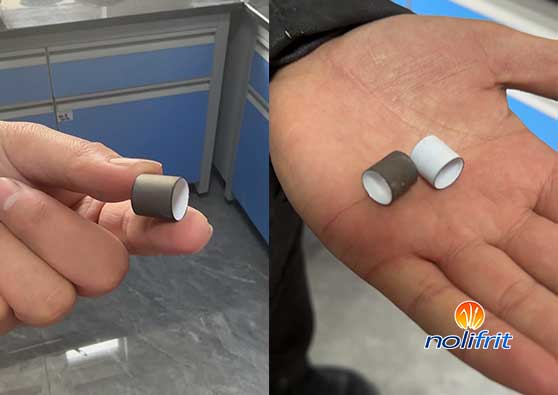

Recently, Nolifrit's R&D center announced an exciting achievement—successfully prototyping enamel mouthpiece components for e-cigarettes. These mouthpieces, made from stainless steel and titanium, are treated with enamel processes, showcasing exceptional corrosion resistance and durability. This innovative development not only brings a new technological breakthrough to the e-cigarette accessory sector but also expands the application boundaries of enamel technology.

Compared to traditional materials for e-cigarette mouthpieces, such as plastic and ceramic, enamel mouthpieces offer significant advantages. Both stainless steel and titanium inherently possess some corrosion resistance, while the enamel coating further enhances this property, effectively resisting the chemical erosion of e-liquid and prolonging the mouthpiece's lifespan. Additionally, the smooth surface of the enamel makes it less prone to retaining dirt and odors, providing a more hygienic experience for consumers.

Nolifrit has a strong foundation in the enamel field, and its R&D team has overcome the technical challenges of achieving high-quality enamel coatings on stainless steel and titanium through numerous experiments and optimizations. From metal surface pretreatment and adjustments to enamel glaze formulations to firing process control, every step has been meticulously refined to ensure the final product meets high-quality standards.

As market demands for product quality and performance continue to rise, more innovative enamel products are expected to carve out a niche in the market due to their unique advantages. Nolifrit is committed to providing technical support to enamel manufacturers with relevant needs, collaborating with the industry to explore further applications of enamel technology in various products and driving technological upgrades in the sector.