Causes of Porcelain Enamel Cracks and Chipping

The defect of porcelain enamel chipping and cracking is often encountered by enamel product manufacturers. There are many reasons for this situation, and one of the very important reasons is related to "stress". So what is stress?

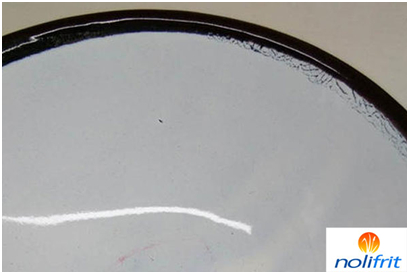

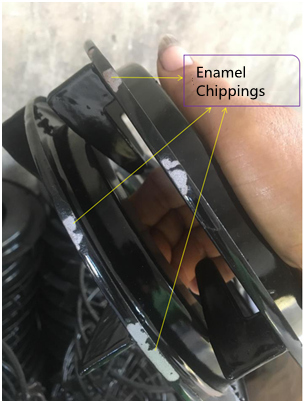

The strength of the enamel layer depends not only on the adhesion of the ground coat and the metal, but also on the magnitude of the stress generated during the processing of the enamel product, which is permanent. The stress generated during use is temporary. The degree of damage to enamel products by stress depends on the elasticity, compressive and tensile strength and thermal expansion of the enamel frit. If the stress exceeds the compressive or tensile strength of the enamel frit, cracks or chippings will occur.

There are many reasons for permanent stress, the most important of which is the difference in thermal expansion between the enamel layer and the metal. The greater the difference in the coefficient of expansion between the enamel layer and the metal, the greater the permanent stress produced after the product is fired and cooled. And there will be more likely to have cracks or chippings on the enamel layer.

So how to solve this phenomenon of enamel product cracks or chippings from the perspective of stress? The answer is to choose a more flexible enamel frit. The better the elasticity of the enamel frit, the better the cushioning performance, and there will be less chance of cracks in the enamel layer due to stress.

Cracks or chippings of the enamel layer caused by stress is also related to the thickness of the enamel layer and the thickness of the metal body. When the thickness of the metal substrate remains unchanged, as the thickness of the enamel layer increases, the elasticity decreases, and the chance of cracking or chippings of the enamel layer caused by permanent stress will also increase; When the thickness of the enamel layer is constant, with the increase of the thickness of the metal substrate, the chance of cracks or chippings of the enamel layer caused by temporary stress will decrease. In order to reduce the possibility of cracks or chippings, it is advantageous to appropriately reduce the thickness of the enamel layer and increase the thickness of the metal substrate.

The shape of mechanical strength of the metal substrate are also related to the cracks or chippings of the enamel layer caused by permanent stress. Generally speaking, if the shape is flat, especially the inner surface of the concave spherical shape, the enamel layer is not prone to cracking or chippings, but the outer surface of the spherical surface is easy to chip. The chance of this kind of enamel removal is also related to the radius of curvature of the spherical surface. The smaller the radius of curvature, the greater the chance of cracking or chippings of the enamel layer caused by stress.

The magnitude of the temporary stress in the enamel layer has a great relationship with the thermal conductivity of the enamel layer. When the product is in use, due to the poor thermal conductivity of the enamel layer, uneven expansion or contraction will occur when heated or cooled unevenly, resulting in stress.

All in all, to make enamel products, we must consider the influence of many factors such as technology and materials. From the modeling style of the metal body, the elasticity and thickness of the enamel, and the overall coefficient of thermal expansion, all the enamel products must be fully considered in the production process. Nolifrit not only supply high-quality enamel frit, but also provide customers with enamel process improvement programs to help enamel companies improve product quality and pass rate. Welcome everyone to contact us.