Adhesion Strength of Porcelain Enamel Coating

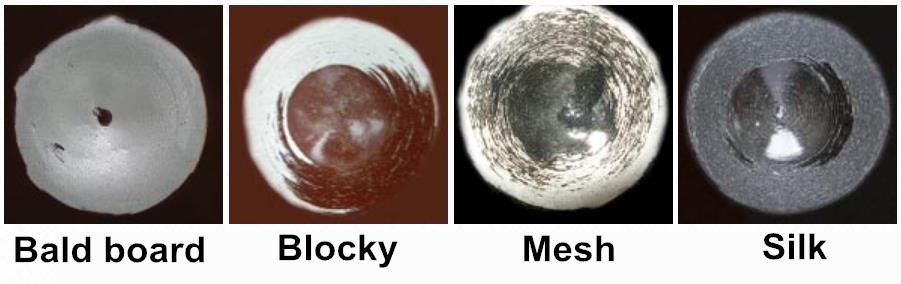

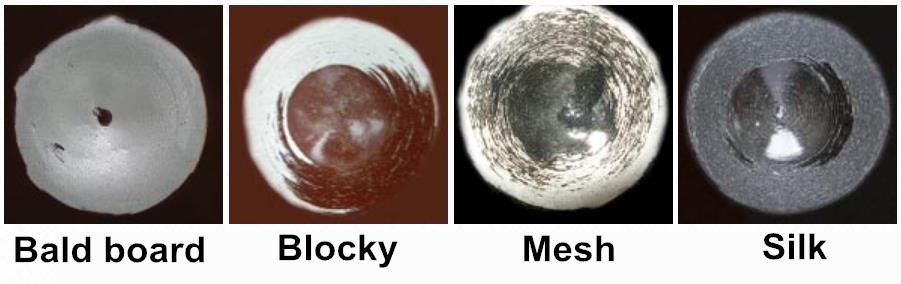

The adhesion strength of the enamel reflects the degree of bonding between the enamel layer and the metal substrate, it is determined by the degree of metal exposure of the enamel layer after the impact of the enamel surface, which is generally divided into four types: silk, net, block and light plate, of which silk is the best, followed by net, block is worse and light plate is the worst.

Silk: the enamel layer is tested and the porcelain layer flakes off to show a small amount of dots and lines of exposed metal.

Silk: the enamel layer is tested and the porcelain layer flakes off to show a small amount of dots and lines of exposed metal.

Mesh: the enamelled layer is tested and the porcelain layer flakes off to reveal the metal in a reticulated form.

Blocky: The enamel layer is tested with a large area of exposed metal after the enamel layer has been peeled off and only a small amount of ground coat is present at the test point.

Bald: the enamel layer is tested and the enamel layer flakes off to reveal all metal.

The five-stage method is currently used abroad to test the adhesion strength of enamels.

The adhesion performance of the enamel and the surface tension of the enamel frit melt has a great relationship. Surface tension and poor wettability of the enamel, can not produce good adhesion with metal.

The adhesion strength of enamels is closely related to the type and quantity of adhesives introduced into the formulation. The introduction of CoO and NiO dense effect is the best, and the introduction of the amount does not need to be very high. Generally, good adhesion can be achieved when the content of C OhO reaches 0.5% or NiO reaches 1%~5%. If CoO and NiO are introduced at the same time, the dense performance will be better, and a certain amount of Sb2O3 and MoO3 can be added to the base coat to improve the dense strength.

The main reason for the introduction of adhesives into the enamel is to promote the infiltration of the molten enamel into the metal surface, the greater the infiltration, the more conducive to adhesion. In addition to the type and quantity of adhesives introduced, the adhesion strength is also closely related to the state of the metal surface and the degree of cleanliness. The adhesion strength of a rough surface is much better than that of a smooth surface.

The degree of fusing of the ground coat has a great influence on the adhesion strength. Fusing too much fusing incomplete, the enamel dense are not good, but also produce other defects. The firing process is also very important for the strength of the enamel products, which can be poor if they are over or under fired.

Mesh: the enamelled layer is tested and the porcelain layer flakes off to reveal the metal in a reticulated form.

Blocky: The enamel layer is tested with a large area of exposed metal after the enamel layer has been peeled off and only a small amount of ground coat is present at the test point.

Bald: the enamel layer is tested and the enamel layer flakes off to reveal all metal.

The five-stage method is currently used abroad to test the adhesion strength of enamels.

The adhesion performance of the enamel and the surface tension of the enamel frit melt has a great relationship. Surface tension and poor wettability of the enamel, can not produce good adhesion with metal.

The adhesion strength of enamels is closely related to the type and quantity of adhesives introduced into the formulation. The introduction of CoO and NiO dense effect is the best, and the introduction of the amount does not need to be very high. Generally, good adhesion can be achieved when the content of C OhO reaches 0.5% or NiO reaches 1%~5%. If CoO and NiO are introduced at the same time, the dense performance will be better, and a certain amount of Sb2O3 and MoO3 can be added to the base coat to improve the dense strength.

The main reason for the introduction of adhesives into the enamel is to promote the infiltration of the molten enamel into the metal surface, the greater the infiltration, the more conducive to adhesion. In addition to the type and quantity of adhesives introduced, the adhesion strength is also closely related to the state of the metal surface and the degree of cleanliness. The adhesion strength of a rough surface is much better than that of a smooth surface.

The degree of fusing of the ground coat has a great influence on the adhesion strength. Fusing too much fusing incomplete, the enamel dense are not good, but also produce other defects. The firing process is also very important for the strength of the enamel products, which can be poor if they are over or under fired.